Every time we visit Ethiopia, on the way south to the coffee growing areas, we always stop at a magical place belonging to a friend of the coffee exporters we work with in Ethiopia – a roadside inn belonging to a huge strawberry growing farm. The coffee there is not really tasty but the strawberry smoothie is amazing. We were very surprised to find out that the farm belongs to an Israeli who immigrated to Ethiopia even before the millennium and we were even more surprised that these strawberries are used in the coffee processing process that will be detailed below.

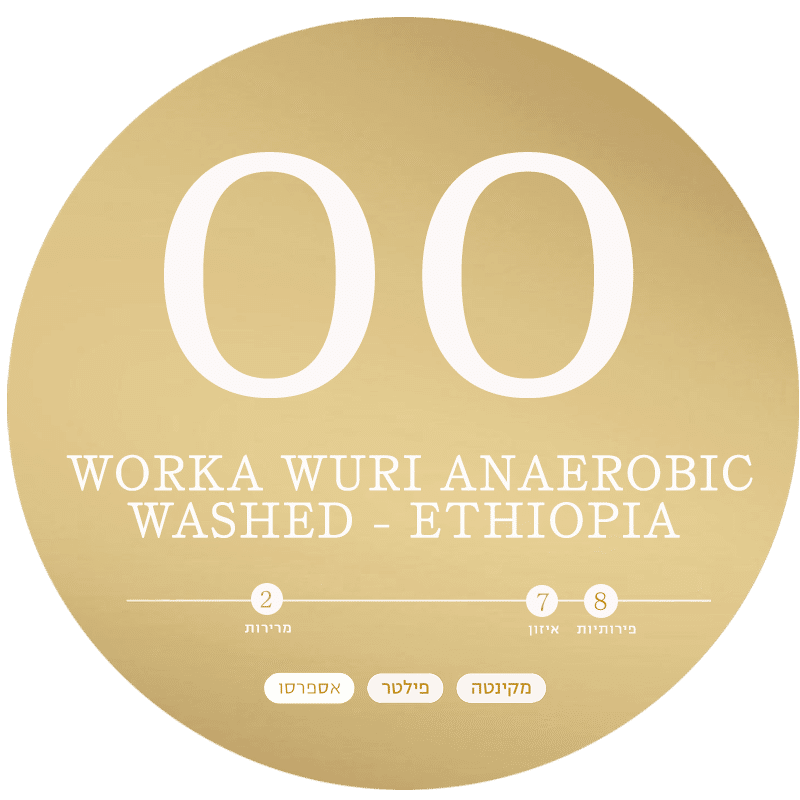

We told a lot about the Worka Wuri washing station, now we will tell about a very special and experimental processing process that this little coffee parcel goes through. First we owe the credit to Jacky Lai – Jacky Lai – the world champion for roasting in 2014, who devised the process in collaboration with our partners in Ethiopia. This trend is gaining momentum around the world and incorporating fruit in the process of processing coffee is still experimental. The idea is to use enzymes and microorganisms that exist naturally in certain fruits and add them to those that are naturally present in coffee cherries in the fermentation process. Each organism breathes and produces energy in a specific metabolic process (metabolism) and the end result varies depending on the fruit we used.

The most beautiful coffee cherries are washed, sorted by hand and placed for anaerobic fermentation (without the presence of oxygen) in large plastic containers along with strawberries (20%). At the top of the tank there is a valve in the shape of a deck through which air bubbles are released out but new air cannot enter the tank. When certain organisms that breathe oxygen (aerobic) use all the oxygen in the container the priority for reproduction and development passes to organisms that use carbon dioxide in the breathing process (anaerobic) which produce completely different flavors after processing. After 72 hours in containers, the cherries undergo a classic washed processing process identical to the classic washed Worka – peeling, soaking in water for another 72 hours and spreading in a single layer on hanging nets for 16 days to dry. The process is very expensive for the coffee because it involves a lot of manpower, constant and close control and a lot of extra work and is generally produced in small portions (1200 kg in total).

What raises the price even more is that the end result has unique taste profiles for the process.

In the world, in addition to a particularly high capping score of 90.3! A rare and very unique experience.